Aerospace and associated advanced manufacturing facilities make great use of investment casting (precision casting), in order to ensure structural integrity and guarantee high performance, and also to cope with what are quite often large, complex forms.

Examples include cast alloy gas turbine blades and other aero engine components.

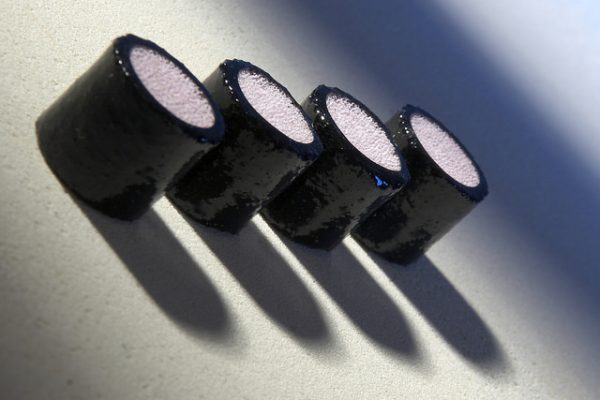

In these applications, Mantec’s Puremet pour filters are positioned within the mould’s gating system to remove non-metallic inclusions such as furnace and ladle slag, moulding sand, refractories and deoxidation products suspended in the metal stream. They also ensure a smooth molten metal flow into the mould. The reticulated, irregular, three-dimensional open cell network of filaments in Puremet filters causes the molten metal to follow a tortuous path through the filter and helps the ceramic material to retain particles much smaller than the pores themselves.

Using Puremet reduces internal re-work costs in welding and cleaning, and improves casting yields and machinability (and hence machine tool life).

For the defence sector, Mantec offers filtration solutions that guarantee safety, long service life, reliability and cost-effective operation in the most demanding situations.

Mantec’s filtration products have been used for several decades on board warships for applications such as breathing air, bilge water and fuel filtration. The filters for breathing air usually comprise a coalescing pre-filter, a carbon adsorber and an after-filter, whereas the bilge and fuel filtration systems are based on Mantec’s Star-Sep™ ceramic crossflow membrane technology.

Aerospace and defence industries around the world generally work to tighter tolerances and are subject to more exacting standards than regular manufacturing environments, and it’s a testament to Mantec’s quality and reliability protocols that its various ceramic filters meet these demands and are readily accepted.