Agrifluids Liquid Fertilizer Recovery

Through the use of an Xtract filtration system, a leading UK agrifluids fertilizer manufacturer pivoted from generating a waste stream which was difficult and costly to dispose of, to recovering valuable and saleable product.

The Challenge – a leading UK agrifluids manufacturer wanted to recover valuable fertilizer liquor from their system washdown water. Historically this waste had been sold as a low grade fertilizer. However, tightening environmental legislation meant that there was no longer a market for this waste. Increasingly high disposal costs of this waste material threatened the very viability of the process, and the business, moving forward.

The Solution – An Xtract crossflow filtration system, using 0.3 micron ceramic membrane technology, was designed specifically for the process and installed on site. This compact system processes 2.5m³ of the system waste material per day which has less than 2% solids concentration.

The PLC controlled system, with a filtration area of 17m², achieves a waste slurry volume reduction of up to 90%, producing a clear liquor containing valuable soluble materials for recycling back into the process or for sale as a stand-alone fertilizer. The system produces a concentrated viscous fluid slurry at 50% solids which is a significant reduction in volume than before and massively reduces disposal costs.

The system runs 24/5 and is operated and maintained by the site’s in-house operations team, having a fully automated in-process cleaning and Clean-in-Place (CIP) system.

The installation of an Xtract filtration system by this leading agrifluids manufacturer turned a process-threatening waste problem into a saleable product output stream, significantly reducing waste disposal costs. Minimising waste and satisfying the latest environmental standards are central to this company’s ISO14001 environmental management system.

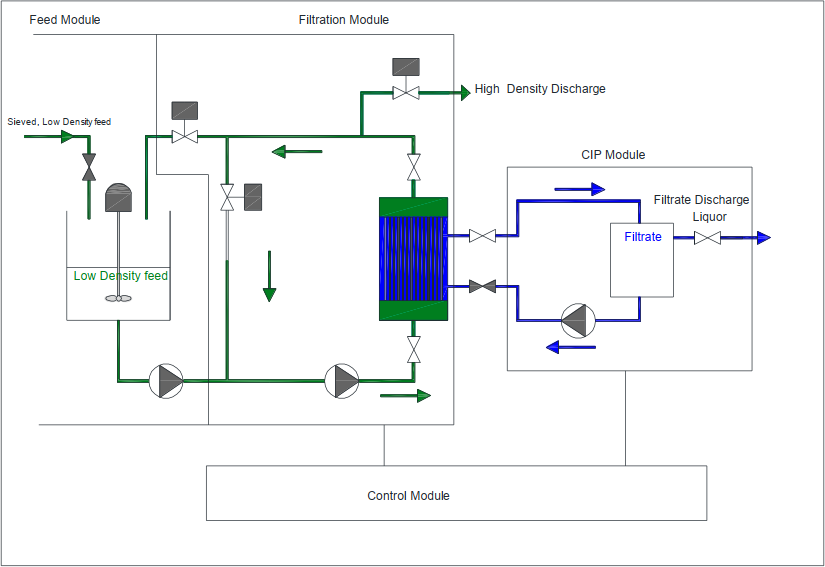

Process Flow Diagram

Cost Savings

The manufacturing plant generates 2.5 m³ of waste material per day, operating five days per week, resulting in 12.5 m³ of waste per week. Prior to the installation of the Xtract system, the waste was tankered away at a typical cost of £7,600 per month (£91,200 per annum).

By implementing the Xtract system, the plant has significantly reduced the cost of waste disposal and enabled raw material savings, achieving a system cost payback of less than two years.

For more information on how Xtract can help recover valuable process materials and reduce disposal challenges in your process please contact Mantec Technical Ceramics Ltd.